1

From our group company Nanbu Kasei

Inherited and cultivated over many years

Lens injection molding technology2

Class 300,000 clean room

3

Production line automation and labor saving

4

Years of experience in mass production

Due to advances in LED technology, headlamp light sources are being replaced with LEDs, and as a result, we are mass producing and supplying resin lenses in response to the demand for traditional glass lenses to be replaced with resin lenses.

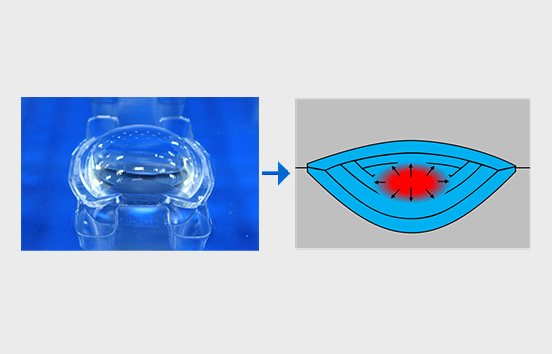

・Outline accuracy 60 μm Freeform surface shape below

・Reconstruction of microstructure shape with nanoscale curvature

・Appearance quality=No foreign objects or dirt (1000Lux light irradiation)

①The free form surface that forms the basic shape of a lens

②Regularly blurring the microstructure of projected images

(Holding amplitude number) μ The concavity and convexity of curvature

Multi layer injection molding technology refers to the ability to construct thick walled parts through multiple thin-walled layers, shorten cooling time, and minimize thermal strain. This can improve production efficiency and reduce costs.

Our dust room system can meet the cleanliness and air flow requirements for production and research equipment.

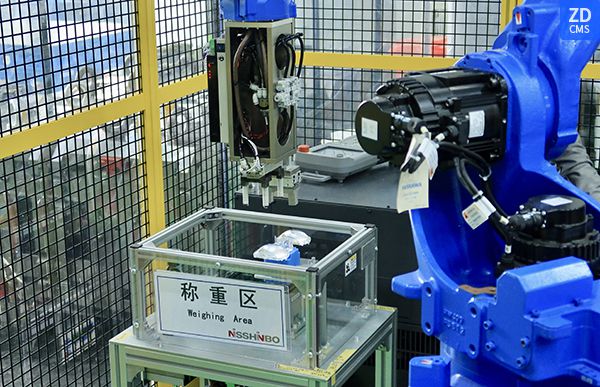

From mold making, product removal, gate cutting, weight detection to static elimination, all processes are carried out using automated robotic arms, avoiding human errors and providing stable quality products through automation.

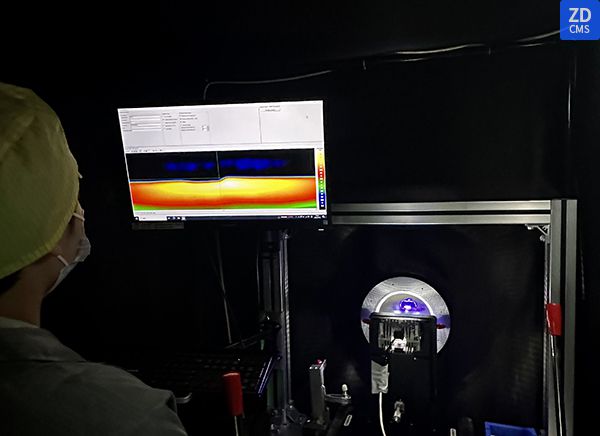

We have a professional optical specification inspection device, which is carried out by professional personnel for appearance and light distribution testing.